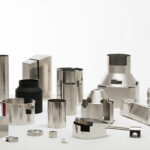

Design, manufacture and delivery of magnetic shielding

Our mastery of complex and varied techniques enables us to respond to all your requests in 9 clearly defined stages to deliver magnetic shielding in permimphy, cryophy, aluminium…

The quality control of our productions is an absolute priority. Thus, the quality is not only controlled at the end of the process but at each of our production steps.

Based in Amilly or in Lyon, your daily contacts will be able to respond to your needs for magnetic shielding in terms of industrial development, design, prototyping, manufacturing, delivery dates, product or system quality within a short period of time and with a competitive offer.

Our production cycle

Click on the links to view our steps

An organization focused on customer satisfaction

MECA MAGNETIC is structured around two sites:

- The production facility in Amilly (45) for industrial development, consultation processing, order management, subcontracting, purchasing, production, final inspection and transverse functions for maintaining operational conditions (maintenance, product and system quality).

Each stage (from design to delivery) is managed on a daily basis to monitor the objectives of requirement and customer satisfaction in a continuous improvement process.

- The head office in Lyon (69), for the general management, financial, commercial and human resources functions. Part of the design office has also moved to the Lyon premises, to respond more effectively to our customers’ requirements.

Magnetic and mechanical design: from need to drawing

The design office responds to all your requests for consultation and costing, from project management in the context of calls for tender, industrial development to the subcontracting of parts to drawings in the shortest possible time in coordination with the customer.

Our qualified teams manage the magnetic design with Comsol and Solidworks for the mechanical design.

MECA MAGNETIC starts from your definition or can help you in the design and quickly provide you with several prototypes (materials, thicknesses and heat treatments), depending on the availability of materials in stock.

We are able to integrate our low-frequency magnetic shielding sub-assembly into a set supplied by our customers or directly, and on customer request, to install it on site.

Magnetic design : from the need to the definition of the means

The starting point for industrial development, this design stage consists of defining, in a theoretical manner, the means necessary to achieve a magnetic field attenuation result.

Thus, the magnetic design can be based on formulas, simulations, prototypes or reasoning by analogy.

Mechanical design: from means to final design

Once the means have been defined, the realization phase (whether on a plan or on specifications) necessarily involves a technical feasibility study of your project.

This will study the risks in terms of shape, dimensioning, integration of the sub-assembly into the final product, resistance, tolerances, risks with regard to heat treatment.

The mechanical design will then consist in drawing the part in Solidworks to allow the realization of the prototypes and then the industrialization with development plans and manufacturing plans, laser cutting programs and the definition of the tools essential to the manufacturing.

Our manufacturing steps : from design to concrete realization

Machine park and investments

In 2020, and despite the COVID 19 crisis, MECA MAGNETIC has reinvested in a modern ERP and is committed to invest regularly in its work tool and to train its teams to new practices, in order to have efficient, modern industrial means and current work practices.

Our workshop is composed of the classic machines used in sheet metal work, completed with equipment dedicated to the production of magnetic shielding.

Our workshop is composed of the classic machines used in sheet metal work, completed with equipment dedicated to the production of magnetic shielding.

We have the following equipment in-house:

- – Cutting equipment: Shears, cutting line, laser cutting (Bystronic), thin laser cutting (Bodor – 2022)

- – Rolling machines

- – Mechanical presses- Digital spinning lathe

- – TIG welding machines, manual, automatic

- – Degreasing machines

- – Drilling machines (2019)

- – Deburring and polishing barrels (2019)

- – Heat treatment furnace under hydrogen (2017), smoke and heat calibration and furnace mapping (2024-2025)

- – Computer servers (2024)

- – Comsol v2024 magnetic design software and Solidworks v2024 mechanical design software

- – Circumferential welding machine (2025)

Shaping based on experienced resources

MECA MAGNETIC identifies and implements the process best suited to the quantity of parts, the required precision, the desired shape (round, square, conical, non-developable). The process can evolve according to the different phases of the product life cycle in order to optimize production and lead times.

For example, a prototype will be made in boiler making, a pre-series in spinning and a series in stamping.

The main processes used are:

- – rolling

- – bending on press brake

- – press tools (rework or speed)

- – embossing

- – stamping

- – shaping….

Standard tolerances: ± 0.15 mm

Heat treatment : a fundamental step in shielding

The added value of a low-frequency magnetic shielding specialist lies in its mastered and integrated know-how in heat treatment, which is defined by cycles.

The latter influences the design as well as the final magnetic result. Ferromagnetic alloys require heat treatment to increase their magnetic properties.

Heat treatment is not a trivial operation and must be planned upstream, from the design stage. It is important to know the characteristics of the furnaces (geometries, sizes, equipment, tools) in order to anticipate the deformations of the parts.

We carry out vacuum or hydrogen treatments in furnaces of different sizes (in-house or subcontracted).

The internal mastery of this process coupled with the daily realization of treatments allows us to be competitive on our prices and reactive. This process is secured at MECA MAGNETIC by special procedures and internal training. A cartography is being developed in order to approach the aeronautical standards.

The choice of heat treatment depends on the following 4 criteria:

- – the magnetic values to be achieved

- – the technology to be used: vacuum or hydrogen

- – the cost involved

- – the constraint linked to the sectoral application: aeronautics, space, cold…

We offer different types of standard to elaborate cycles, allowing to reach relative permeabilities from a few tens to several hundreds of thousands. It is possible to realize very specific heat treatment cycles in case of specific constraints and qualifications.

Assembly

The choice of assembly will depend on the desired magnetic efficiency, environmental constraints and feasibility. This may have a significant impact on the cost.

The main processes used are :

- – TIG welding- laser welding

- – electric welding

- – gluing

- – mechanical fastening by components (crimping nuts, rivets…)

- – mechanical fastening by deformation or interlocking

It should be noted that TIG and laser welding ensure perfect magnetic continuity. The other manufacturing processes generate a more or less important air gap.

TIG welding is a special process used daily at Meca Magnetic by experienced professionals.

A qualification of the welding procedures is in progress, in order to assure our customers of a repeatability in the execution…

Surface treatment

Appearance paints and protection against oxidation are the main problems of surface treatment. We will be able to advise you and guide you if necessary.

MECA MAGNETIC has a network of partners who, on a daily basis, dress the armor in order to protect it against deterioration risks (such as oxidation) or to make it look good.

Obviously, when choosing the surface treatment, care must be taken to ensure that it does not overheat the part and remains far from the Curie temperature.

- Appearance paint

MECA MAGNETIC has a network of painters adapted to iron-nickel alloys by the powder or liquid application technique. The selection of specific paints will be defined at the product design stage (e.g.: medical, radioactivity-free, etc.)

- Oxidation protection

For pure iron and alloys with 36% nickel, it is strongly recommended to protect the shielding against oxidation. Paints can be used, but also nickel plating, tinning…

Other more marginal and therefore more expensive solutions such as cadmium plating (increase in corrosion resistance), gilding, etc. can be considered.

Finishing operations

After heat treatment, some shields continue a manufacturing process of finishing integrating : reconformation, integration in other components, addition of specific functions… The identification of these final operations is of course carried out in the answer to the consultation request.

MECA MAGNETIC can, thanks to its specific know-how, ensure the integration of shielding parts in an existing assembly composed of different materials. This service is carried out at the request of the customer.

Final control : release of quality products

Self-control and control

MECA MAGNETIC ensures a self-control throughout its process in 9 steps.

In addition to this self-checking, the final control operation and all the documentary management linked to the requirements of traceability and conservation of the customers’ data.

These control operations, carried out under the supervision of the production manager, are essential for the release of products.

The objective is to satisfy the defined and planned customer requirements. For MECA MAGNETIC, quality is an important element of customer satisfaction.

The calibration of measuring instruments, necessary for these control operations, is carried out by a COFRAC establishment in dimensional metrology. The controls/self-checks can be unitary, by sampling (method ” AQL – Single reduced inspection ” – ISO 2859-1) or at 100 %.

The mechanical and magnetic controls are defined at the design stage of the part, according to the requirements specified by the customer.

- Mechanical inspection

MECA MAGNETIC foresees from the beginning the mechanical control operations specific to the boiler making, fine sheet metal work according to the typology and the format of the shields produced, and the size of the possible series. Controls can be reinforced during the life cycle of the product.

We can mention for example : a control on plan with classic metrology, a 3D inspection, a control gauge, such as GO NOGO (…).

- Magnetic inspection

It must be specified and planned from the beginning because it is, most of the time, carried out starting from control washers resulting from the same material as the parts and placed in the same heat treatment. If the requirement increases, it is possible to plan an evolution of the control on this point.

A magnetic control on washer allows to know : µi, µmax, Hc, Bs.

In accordance with the customer’s requirements, it is necessary to define whether the measurement is to be made in a direct or alternating field.

Packaging, delivery, identification of parts, installation on site

Magnetic shields are fragile parts. It is therefore advisable to foresee their packaging at the beginning of the project because it can be very specific.

MECA MAGNETIC can propose:

- – individual packaging in silk, bubble or kraft paper, custom-made dividers, in plastic boxes or using impression foam

- – cardboard packaging, custom-made wooden crates

- – any container adapted to a specific request

On regular productions, MECA MAGNETIC will favor the use of recyclable shuttle boxes allowing a better protection of the parts and a respect of the environment.

- The parts are delivered identified with a label showing the customer reference, the internal reference, the manufacturing batch (or more if specifically requested by the customer).

The means are the Material to be used, thickness, volumes, shape of the shielding, appropriate heat treatment.

The Curie temperature (or Curie point) of a ferromagnetic or ferrimagnetic material is the temperature TC at which the material loses its permanent magnetization.